Explore our full range of laser intelligent equipment, designed for efficiency, stability, and precision machining.

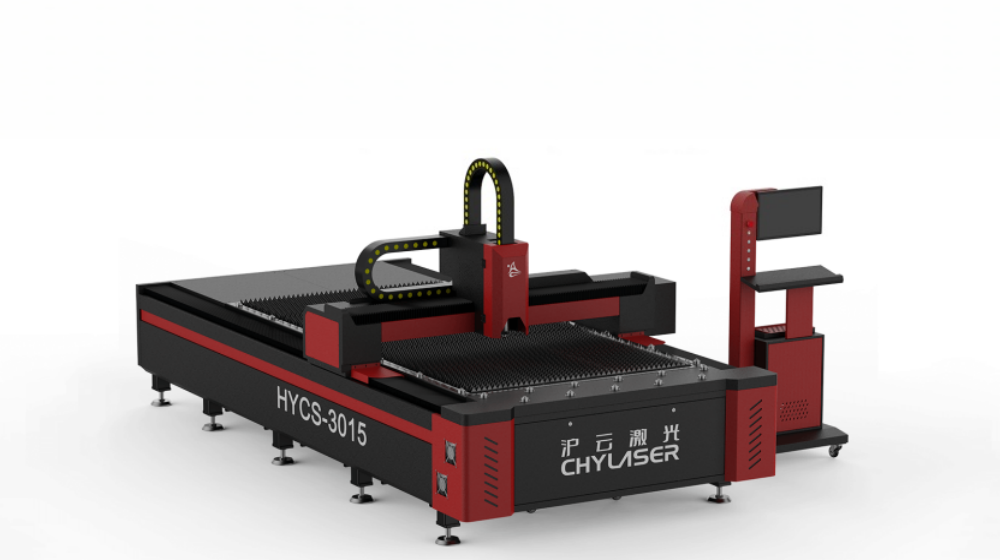

Single table laser cutter combines efficient continuous cutting with high precision. Open single worktable design simplifies loading/unloading, enabling uninterrupted operation to save time and boost productivity.

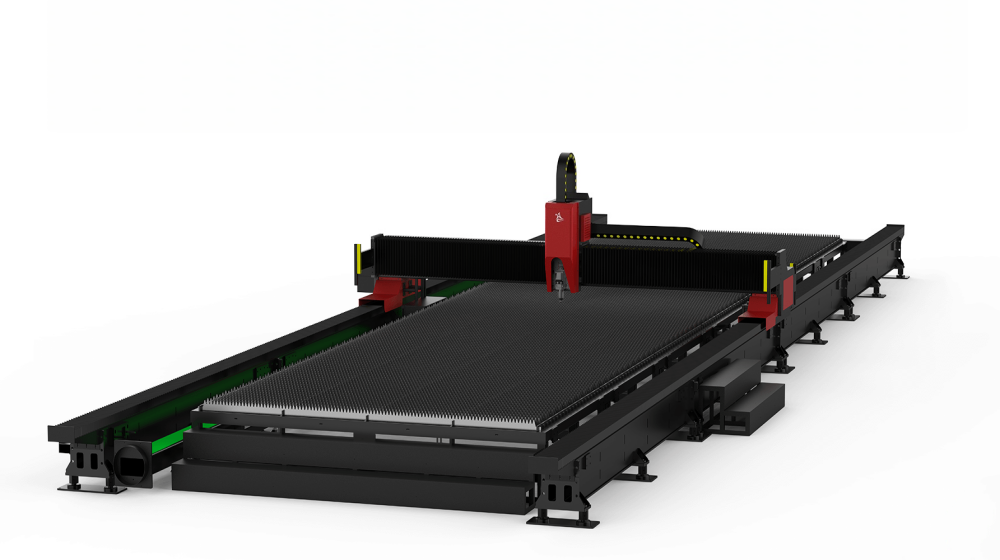

Rail gantry laser cutter designed for oversized heavy plates. Features large working area and excellent rigidity for high-precision, efficient large-scale metal component processing.

Dual worktable design enables continuous cutting and loading/unloading simultaneously, eliminating downtime and maximizing equipment utilization and productivity.

Three-chuck synchronized rotation and support system for efficient long tube processing. Continuous feeding and cutting without tube rotation, significantly improving productivity and stability.

Dual-chuck synchronized drive for precise centering and stable cutting. Saves material, ideal for short tubes and high-precision, efficient processing.

Compact and economical single-chuck tube cutter. High rigidity, small footprint, ideal for precision rapid cutting of small to medium batch short tubes.

Flexible handheld operation like a welding torch. Remote high-quality welding of complex parts with minimal heat input and deformation, easy operation without professional skills.

CNC platform or automation system for precise positioning and automatic welding. Ensures high consistency and quality for batch production of precision components.

6-axis industrial robot with high-power laser head. Offline programming for flexible 3D trajectory processing including cutting, welding and cladding.

High-dynamic 5-axis simultaneous movement for high-precision multi-angle cutting of complex 3D curved parts. Designed for aerospace, automotive mold industries.

Permanent, fine non-contact marking on various materials. Fast, precise, versatile and consumable-free. Core equipment for product identification and traceability.

Non-contact, damage-free surface cleaning. Instant removal of rust and coatings without consumables. Efficient green cleaning for molds, welds restoration.

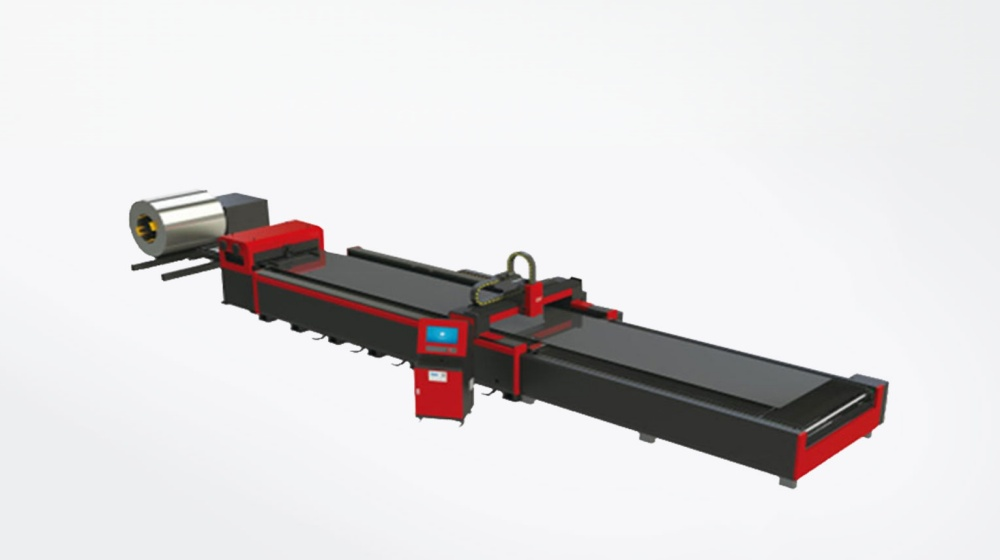

Integrated uncoiling, leveling and cutting for continuous automated processing of metal coils. Saves material and tooling costs. Ideal for sheet metal batch production.

Built for ultimate precision. High rigidity structure and precision control for micron-level cutting, smooth burr-free edges. Ideal for precision parts and thin sheets.

Combined sheet and tube cutting in one machine. Dual capability for flexible efficient processing of both materials, saving equipment investment and floor space.

Integrated automatic loading/unloading, smart sensors and control systems for unmanned, flexible and intelligent laser processing. Core unit for smart factories.

Beyond standard configurations, we focus on providing deeply customized laser application solutions for your unique manufacturing challenges. Leveraging a 40+ R&D team, 200+ patented technologies, and extensive industry experience, we collaborate comprehensively from materials and processes to production line integration, ensuring the solution precisely matches your production goals and brand requirements.

Contact Us